In 1987, Andrew Landenberger starts to build the first sails in Australia under his own label.

In 1989, "Landy" won the Australian Championship and World Championship in the Moth class with a clean sweep. Andrew's desire to build fast sails led to more and more focus on professional sailing and sailmaking.

In 1996, Andrew won an Olympic silver medal in Atlanta in the Tornado class with Mitch Booth. Since then, Andrew has dedicates his full energy to sailing.

In 1997, Andrew decided to move with his family to Germany. Soon after he started under the Ullman label as Ullman Sails Germany the sails production in Titisee.

In 2001 he founded his own label Landenberger Onedesign and further expanded the production.

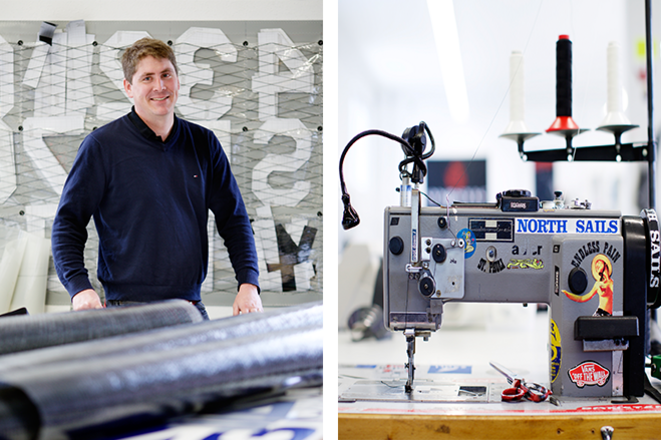

In 2004, Felix Egner joins the company, Felix is a trained sailmaker and has completed his training with the renowned Sailloft "Fritz sails" in Prien am Chiemsee.

In 2005, Andrew and Felix sailed the Topcat K1 World Championship "just for fun" to become world champions. In 2006 they become third at the F18 World Championship.

In 2008, Henning Runge started working as a sailmaker at Landenberger Onesdesign, Henning previously worked as a sailmaker at North Sails, Wendel and Rados, and Faber and Münker.

In 2016, Felix Egner takes over Landenberger Sailing and continues the sail label Landenberger OneDesign.

Meanwhile, sailmaking is a full time job and Felix keeps the company going. Andrew has since started a coaching career and finished it in 2016 with an Olympic silver medal as coach of Jason Waterhouse and Lisa Darmanin in Rio.

Currently he runs his farm in Australia and continues to work as a consultant for the sailloft, supporting us during the cold season with sailing tests in Australia.

Although Andrew now spends more time designing sails and farms, he is still one of the world's leading multi-hull sailors.